Rise of Poly V Belts: A Revolutionary Solution in Power Transmission

The Poly V Belt is a high-performance cord-reinforced transmission belt perfected for every modern mechanical system. Its informativeness, high performance, and compactness make it essential in various spheres. This article provides information about the design and advantages of using Poly V Belts.

Effective Design Parameters

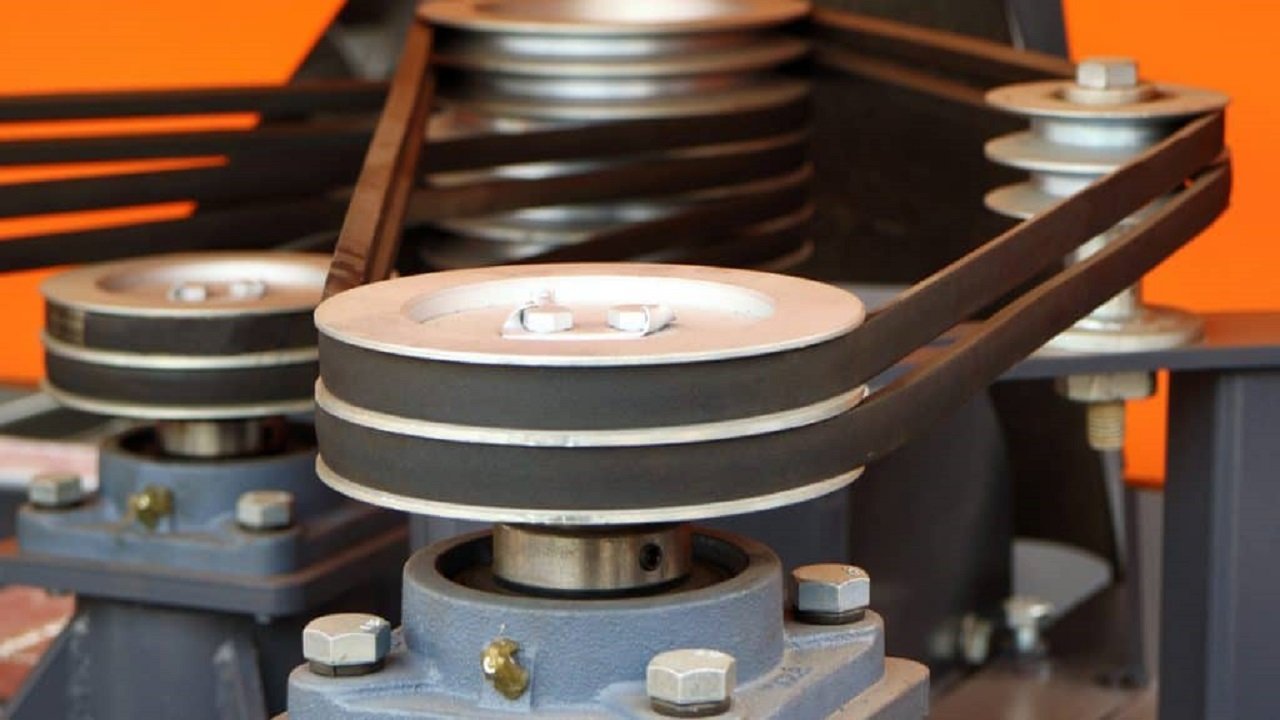

Triangular-shaped ribs running along the length of the Poly V Belt offer a vital look and remarkable functionality at the same time. These ribs also afford better protection to the reinforcement cords, enabling a balanced load during operation. The construction of this belt avoids any contact with cords, and hence, the durability and reliability of the belt are greatly enhanced. Additionally, the Poly V Belt can accommodate either an idler pulley or even a belt tensioner; therefore is quite versatile. It has enhanced mechanical properties to work at greater tension without getting elongated, as is preferred in its functions.

Space-Saving Efficiency

Another vital advantage of the Poly V Belt is its efficiency in confined and small areas. Compared to V-belts or flat belts, Poly V Belts call for less space when used, making it the best belt for modern-day machinery designs that don’t provide much space. Another advantage of the belt design is the tolerance for a pulley, even with a minimum diameter of 9mm, indicating the structure’s compactness. It seems that this feature permits more compact arrangements and decreases the size and weight of the mechanical system, thereby increasing its efficiency.

Superior Contact Surface Area

Brands like ZZR develop V belts with a larger contact surface area than the standard and flat belt. This guarantees an increased contact area, thus allowing efficient power transmission with minimal slippage, as may be the case when loads are applied. Due to enhanced grip and steadiness over a wide power range, these V belts produce constant tractive force in high torque operation and, hence, decrease the sheer stress experienced by the system.

Endurance and Reliability

The Poly V Belts are designed for durability in a challenging operational environment and are based on cord reinforcement. They can also sustain high tension substantially without excessive stress and cracking or elongation in unfriendly environmental conditions. This durability makes it easier to require minimal maintenance; it has a long lifespan and therefore makes the overall operation cost low. Due to the load being evenly distributed across the ribs of the poly V belt, this is one belt that you can ultimately bet your cash on. For this reason, the Poly V Belt reduces stress concentrations, thus making the operations smoother and will not quickly fail.

Uses of the Poly V Belt

This poly V belt’s strength and flexibility are unmatched, making it suitable for various applications. In addition to residential appliances, they are utilized in industrial settings, car engines, and HVAC systems. Their small size and features enable high performance and make them suitable for operation in small or large projects.

Conclusion

The Poly V Belts are a significant innovation in power transmission technology. Their elegance, smooth contact surface, compactness, and high endurance make them relevant in most contemporary mechanical applications. In many cars, industries, or households, the Poly V Belt can meet the new and high demand for power transmission.