Modern engineering and industry depend heavily on thermal management. Heat is a consequence of many industrial operations, and if it is not controlled, it may harm delicate electrical components or even cause machinery to break down. Using cold plates, which are metal plates that have been carefully constructed to swiftly and effectively absorb and release heat, is one way to solve this issue.

Many electronics businesses rely on cold plate manufacturers to deliver specialized cold plate solutions that satisfy their unique cooling needs. These producers possess the knowledge and tools required to produce cold plates that satisfy the particular cooling specifications of each application.

We will talk about the best cold plate producers in this piece so they can satisfy your thermal management requirements.

What are cold plates?

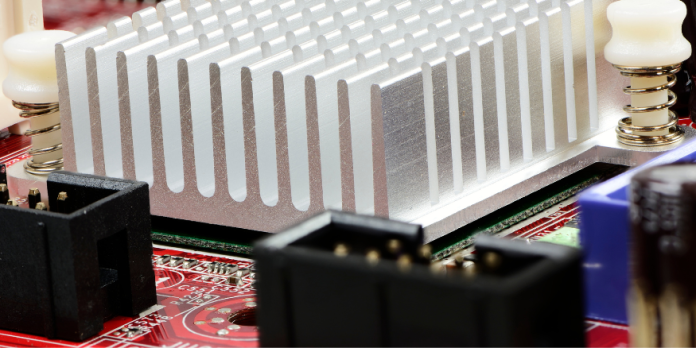

A flat, metal surface called a “cold plate” is used to cool down electrical parts. The plate often consists of copper or aluminum and includes a number of grooves or channels that let coolant flow through them. The coolant absorbs the heat and transports it away from the plate when the heat-generating components are installed on the cold plate, enabling the components to run at a safe temperature.

A cold plate is a heat sink made of a flat metal plate with internal channels that move a cooling fluid, such water or a refrigerant, throughout. Copper and aluminum have a high heat conductivity; hence they are frequently used to make cold plates. The fluid flowing through the channels transfers the heat from the electronic components to the cold plate and away from the plate to an external heat exchanger.

Why use cold plates?

Due to their high efficiency in removing heat, cold plates are a fantastic thermal management option. They may be tailored to match the unique requirements of a given application and can be made to fit practically any shape or size. Moreover, cold plates are incredibly dependable and require very little upkeep. Because they don’t utilize any hazardous chemicals or refrigerants, they are also ecologically friendly.

How Does Cold Plate Technology Work?

A processor or power supply are examples of electronic components that generally have the cold plate installed on them or close by. Direct contact between the electronic parts’ heat-producing surfaces and the cold plate results in heat transfer.

An external heat exchanger receives the heat from the cold plate by way of the internal channels of the cold plate, which also circulate a cooling fluid. The heat exchanger might be a straightforward radiator that is air-cooled or a more intricate liquid-to-liquid heat exchanger.

Types of Cold Plate Technology

Cold plate technology comes in single-phase and two-phase varieties. To remove heat from the electrical components, single-phase cold plates employ a liquid coolant, such as water or glycol. Refrigerant used in two-phase cold plates, such R134a, cycles through the cold plate’s internal channels as it evaporates and condenses. Since the latent heat of vaporization absorbs a significant amount of heat energy that may be quickly transported away, two-phase cooling is more effective than single-phase cooling.

Advantages

Comparing cold plate technology to other cooling techniques reveals various benefits. The first benefit is that it is a very effective cooling technique that can efficiently remove a lot of heat energy from electronic components. Second, cold plates are a perfect choice for high-performance computing and industrial applications because they can be tailored to accommodate particular electrical components.

Lastly, unlike fans or other mechanical cooling techniques, cold plates are silent and do not produce noise. Lastly, because it employs water or other non-toxic coolants and has the potential to recover waste heat for various applications, cold plate technology is ecologically benign.

Bonus Read

Electronic component cooling with cold plate technology is effective and scalable. High efficiency, silent operation, and environmental friendliness are just a few benefits it has over conventional cooling techniques. In high-performance computers, electric cars, aircraft, and medical equipment, cold plate technology is frequently employed. Cold plate technology will be even more essential for preserving maximum performance and dependability as electronic gadgets continue to grow more powerful and smaller.